Rotary Friction Welding

Rotary friction welding is a type of pressure welding performed in a solid state. It is a method of joining by applying pressure using friction heat.

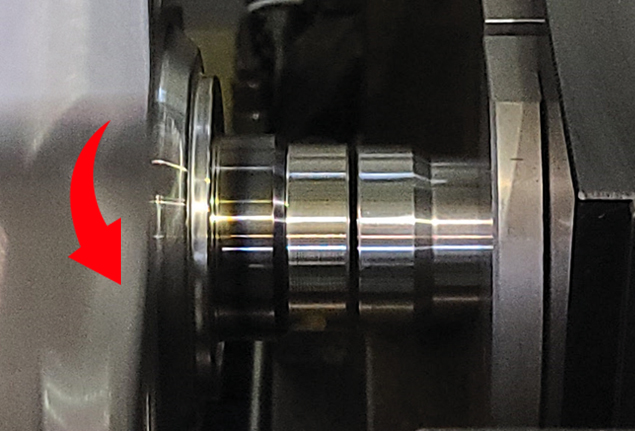

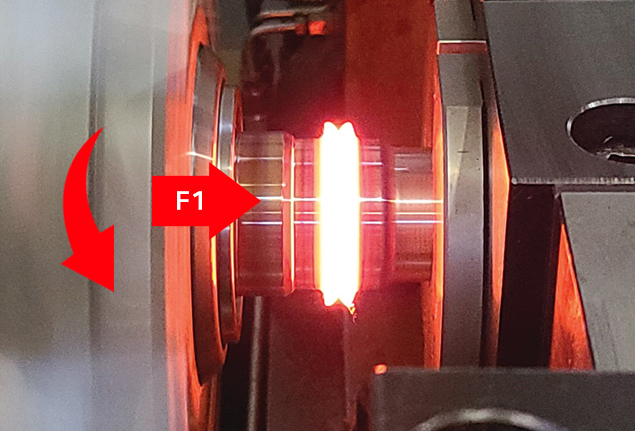

When a rotating material is brought into contact with a fixed material by applying primary pressure (friction pressure), heat is generated by friction at the contact surface and impurities, including oxides, are removed in the form of burrs.

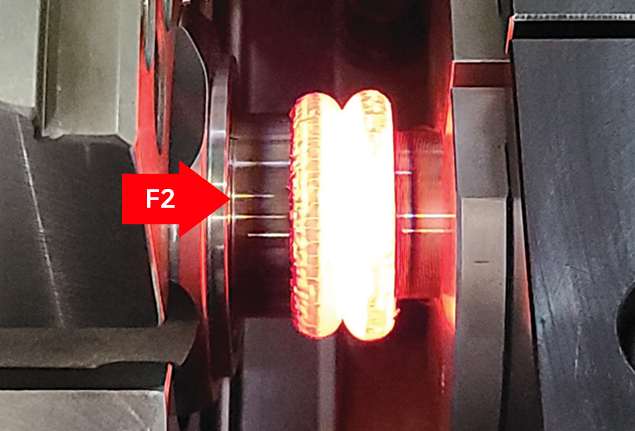

When the contact surface is deformed plastically by frictional heat, it stops rotating.

It is then joined through the application of a secondary pressure (forge pressure), whereby the two materials are strongly bonded through attraction or diffusion between atoms.

Work Process

-

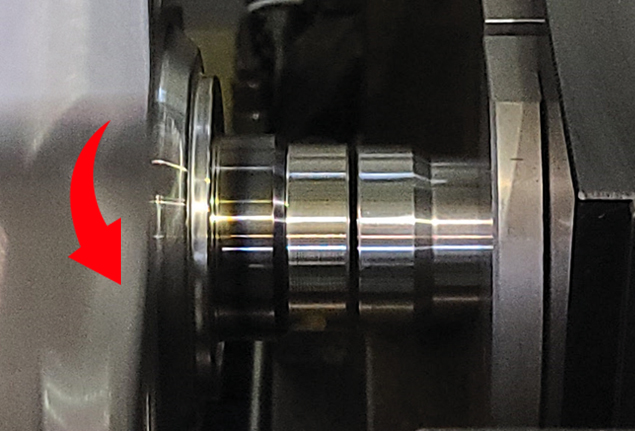

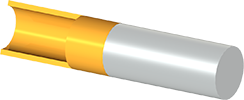

STEP 01. Fixing and rotating materials

Apply primary pressure to fast rotating and fixed materials.

-

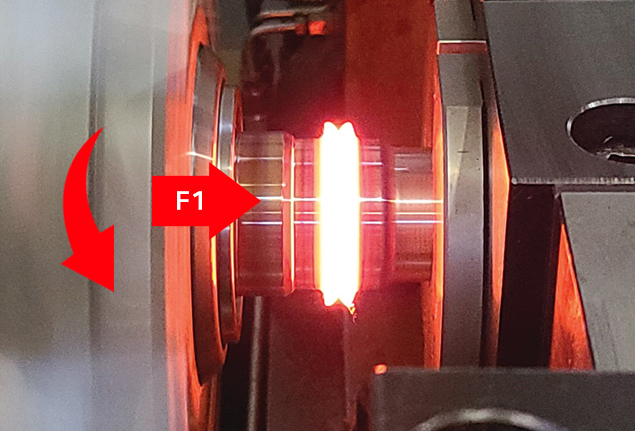

STEP 02. Friction pressurization

When pressure is applied continuously, plastic deformation occurs due to frictional heat on the contact surface.

-

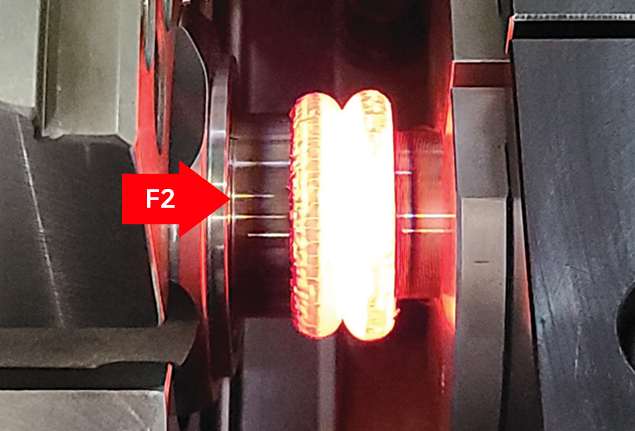

STEP 03. Pressurization and completion of forging

Stop rotating and momentarily apply strong secondary pressure to the material in contact.

Advantages of Friction Welding

Friction welding is a solution that improves quality and productivity.

-

Improved Quality

- · There were no defects found in the existing welding method (pores, spatter, etc.).

- · Stable bonding strength can be obtained because the entire bonding surface is bonded.

- · The cured area can be minimized because there are few heat-affected areas.

- · High dimensional accuracy with low thermal deformation can be obtained because heat is evenly dispersed.

-

Reduced Production Costs

- · No consumables, such as welding rods or gas, are required and no special improvement process is required.

- · Material, processing, and forging costs can be reduced through weight reduction and optimization of parts.

- · Various material combinations are possible because dissimilar metals and nonferrous metals can be bonded.

- · Energy consumption is 5 - 20% less than for other welding methods.

-

Improved Production Efficiency

- · Operation is easy and no special technology is required.

- · Consistent and repetitive reproducibility made possible through machine control.

- · Defective product analysis is possible through real-time monitoring and storage of welding results data.

- · Welding time is very short.

- · Attaching an automated device enables unmanned operation, which can increase the operation rate of the facility.

-

Environmental Improvements

- · Eliminating the need for consumables or gas contributes to the protection of the natural environment.

- · The almost total lack of any harmful gas, spatter, or glare makes it an environmentally friendly option.

- · Carbon dioxide emissions are half those of other welding methods.

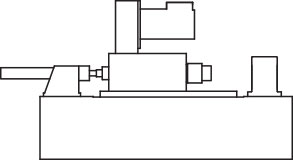

Basic Friction Welding Equipment

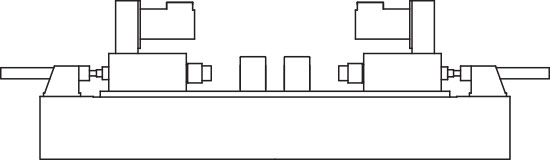

Hydraulic Friction Welding Machine

| Technical Data |

8 SF/DF |

15 SF/DF |

30 SF/DF |

60 SF/DF |

100 SF/DF |

125 SF/DF |

| Maximum Forging Thrust |

Ton |

8 |

15 |

30 |

60 |

100 |

125 |

| Spindle Motor |

kW |

17.5 |

22 |

37.5 |

55 |

90 |

112 |

| Maximum Rotating Speed |

RPM |

3,000 |

2,500 |

2,000 |

1,300 |

1,000 |

1,000 |

| Welding Capacity (Mild Steel Bar) |

mm |

4~28 |

8~38 |

20~50 |

25~80 |

45~100 |

50~125 |

| Maximum Welding Area (Mild Steel Bar) |

mm² |

600 |

1,100 |

2,000 |

5,000 |

7,850 |

11,500 |

CNC friction welding machine (Servo phase control)

| Technical Data |

CNC 5SF/DF |

CNC 8SF/DF |

CNC 12SF/DF |

CNC 22SF/DF |

| Maximum Forging Thrust |

Ton |

5 |

8 |

12 |

22 |

| Phase Angle |

Angle |

±0.5° |

±0.5° |

±0.5° |

±0.5° |

| Maximum Rotating Speed |

RPM |

3,000 |

2,500 |

2,000 |

2,000 |

| Welding Capacity (Mild Steel Bar) |

mm |

6~20 |

8~25 |

10~30 |

15~45 |

| Maximum Welding Area (Mild Steel Bar) |

mm² |

350 |

500 |

800 |

1,500 |

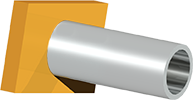

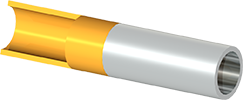

Shape of the Friction Welded Joint

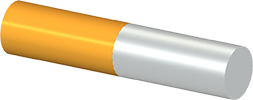

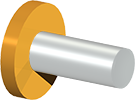

Bar to Bar

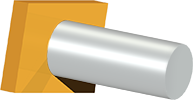

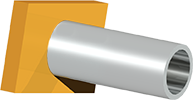

Bar to Plate

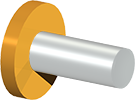

Bar to Disk

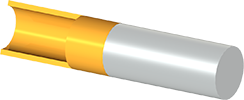

Tube to Bar

Tube to Plate

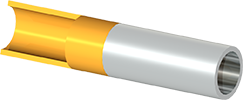

Tube to Tube